Jinjiang Jili Machine Co., Ltd.

Single Color EVA Foam Injection Machine

Single Color EVA Foam Injection Machine

Two Color EVA Shoes Injection Machine

Two Color EVA Shoes Injection Machine

Two Color Rotary PVC Boot Making Machine

Two Color Rotary PVC Boot Making Machine

Single Color Rotary PVC Boot Injection Machine

Single Color Rotary PVC Boot Injection Machine

Rotary PVC Children Boot Making Machine

Rotary PVC Children Boot Making Machine

PVC Blowing Shoes Injection Machine

PVC Blowing Shoes Injection Machine

JIC506B Three Color PVC Flip Flops Strap Injection Machine

JIC506B Three Color PVC Flip Flops Strap Injection Machine

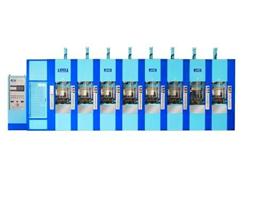

JIC806 Three Color PVC Flip Flops Strap Making Machine

JIC806 Three Color PVC Flip Flops Strap Making Machine

EVA Sole Injection Moulding Machine

EVA Sole Injection Moulding Machine

PVC Sole Injection Moulding Machine

PVC Sole Injection Moulding Machine

|

MODEL |

PS-98 |

|

Screw diameter |

65mm dia. × 1. |

|

Max. Injection volume per shot |

750 cm3 × 1 |

|

Max. Mould Stations |

Single station, one station for one pair injection. |

|

Mold dimension |

300 × 400mm× 2 |

|

Max. Mould Height |

200 mm |

|

Clamping Force |

130tons |

|

Opening stroke |

250mm |

|

Number of temperature control |

3 section |

|

Motor or screw Driving |

Hydraulic Driving |

|

Total Power Consumption |

22.5 kW |

|

Machine Measurement |

1980 × 3100 × 2050mm (L× W × H) |

Tag: Pin Insertion Stiletto Heels Injection Molding Equipment | Pin Insertion Stiletto Heels Injection Moulding Machine | Automatic Pin Insertion Stiletto Heels Injection Equipment | Auto Pin Insertion Stiletto Heels Injection Machinery

Tag: EVA Shoes Injection Molding Line | EVA Shoes Injection Molding production Line | EVA Shoes Injection Molding equipment | EVA Shoes Injection Molding Machinery